Axial Flux Motors

1. Fundamental Magnetic Flux Orientation

graph LR

subgraph "Radial Flux Motor"

A[Stator] --> B[Air Gap]

B --> C[Rotor]

D[Flux Direction: ⟂ to shaft]

end

subgraph "Axial Flux Motor"

E[Stator Disc] --> F[Air Gap]

F --> G[Rotor Disc]

H[Flux Direction: ∥ to shaft]

end

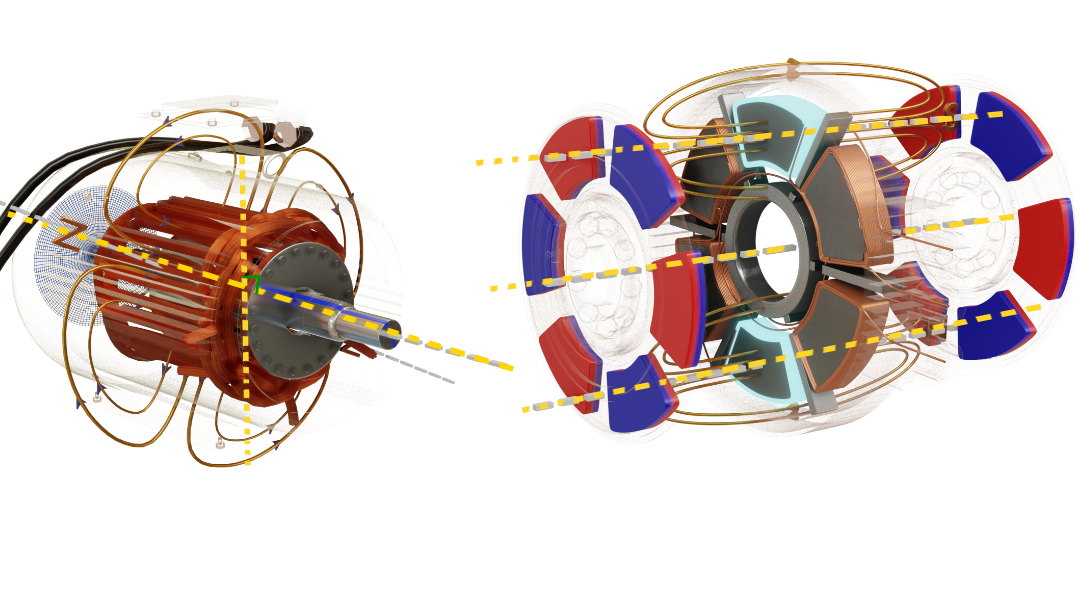

Radial Flux Motors (Traditional)

- Flux Direction: Magnetic flux flows radially from rotor to stator (perpendicular to shaft axis)

- Air Gap: Cylindrical air gap between rotor and stator

- Magnetic Circuit: Flux crosses the air gap in the radial direction

- Field Distribution: Magnetic field lines are perpendicular to the axis of rotation

Axial Flux Motors

- Flux Direction: Magnetic flux flows axially along the shaft direction (parallel to shaft axis)

- Air Gap: Flat, disc-shaped air gap(s) parallel to rotor face

- Magnetic Circuit: Flux crosses the air gap in the axial direction

- Field Distribution: Magnetic field lines are parallel to the axis of rotation

2. Construction Architecture

graph TD

subgraph "Radial Flux Construction"

A1[Cylindrical Stator] --> A2[Slotted Core]

A2 --> A3[Distributed Windings]

A4[Inner Rotor] --> A5[Magnets/Windings]

A5 --> A6[Cylindrical Air Gap]

endgraph TD

subgraph "Axial Flux Construction"

B1[Disc Stator] --> B2[Concentrated Windings]

B3[Disc Rotor] --> B4[Surface Magnets]

B4 --> B5[Flat Air Gap]

B6[L/D Ratio less than 0.3]

endRadial Flux Design

Traditional cylindrical construction:

- Stator: Cylindrical with slots for windings

- Rotor: Inner cylinder with magnets/windings

- Length/Diameter Ratio: Typically

- Cooling: Radial heat dissipation paths

Axial Flux Design

Disc-like construction:

- Stator: Flat disc with concentrated windings

- Rotor: Disc with surface-mounted magnets

- Length/Diameter Ratio: Very low

- Cooling: Axial heat dissipation through large surfaces

3. Electromagnetic Theory Differences

graph LR

subgraph "Torque Generation"

A[Magnetic Field B] --> C[Force on Conductor]

B[Current I] --> C

C --> D[Torque = r × F]

end

subgraph "Scaling Laws"

E[Radial: T ∝ D²L]

F[Axial: T ∝ D³]

endTorque Production

Radial Flux:

- Active length is axial dimension

- Torque density limited by radial magnetic loading

Axial Flux:

- Active area scales with radius squared

- Higher torque density potential at larger diameters

EMF Generation

Radial Flux:

where

- Flux linkage through cylindrical surface

Axial Flux:

where

- Flux linkage through disc surface

- Higher EMF at larger radii due to increased velocity:

4. Magnetic Circuit Analysis

graph TD

subgraph "Radial Flux Path"

A1[N Pole] --> A2[Air Gap]

A2 --> A3[Stator Tooth]

A3 --> A4[Stator Back Iron]

A4 --> A5[Return Path]

A5 --> A6[S Pole]

end

subgraph "Axial Flux Path"

B1[N Pole] --> B2[Axial Air Gap]

B2 --> B3[Stator Core]

B3 --> B4[Radial Return]

B4 --> B5[S Pole]

endReluctance Considerations

Radial Flux:

where

- Magnetic path through cylindrical iron core

- Flux density uniform across air gap height

Axial Flux:

where

- Magnetic path through disc-shaped iron core

- Variable reluctance with radius

- Non-uniform flux density (higher at inner radius)

Leakage Flux

Radial Flux:

- End-turn leakage at motor ends

- Slot leakage between conductors

- Predictable leakage patterns

Axial Flux:

- Edge effects at disc periphery

- Inter-disc leakage in double-sided designs

- 3D magnetic field effects more significant

5. Power Density & Scaling Laws

graph LR

subgraph "Scaling Relationships"

A[Radial: P ∝ D²L] --> C[Linear Volume]

B[Axial: P ∝ D³] --> D[Cubic Diameter]

endgraph TD

subgraph "Heat & Surface Area"

E[Heat ∝ Surface Area] --> F[Radial: ∝ DL]

E --> G[Axial: ∝ D²]

endRadial Flux Scaling

where

- Limited by aspect ratio constraints

- Heat dissipation through cylindrical surface

Axial Flux Scaling

- Superior scaling for larger diameters

- Heat dissipation through flat surfaces

- Better power-to-weight ratio for large diameters

Power Density Comparison:

where

6. Winding Configurations

flowchart TD

A[Radial Windings] --> B[Long End Turns]

C[Axial Windings] --> D[Short End Turns]

B --> E[Higher Resistance]

D --> F[Lower Resistance]Radial Flux

- Distributed windings: Conductors spread across multiple slots

- Concentrated windings: Each coil around single tooth

- Resistance:

where includes long end turns - Standard 3-phase winding arrangements

Axial Flux

- Toroidal windings: Around disc core (less common)

- Concentrated non-overlapping: Each coil encircles single tooth

- PCB windings: Flat spiral conductors

- Resistance: Lower due to shorter end turns:

7. Performance Characteristics

graph TD

A[Losses] --> B[Copper I²R]

A --> C[Iron Core]

A --> D[Mechanical]graph LR

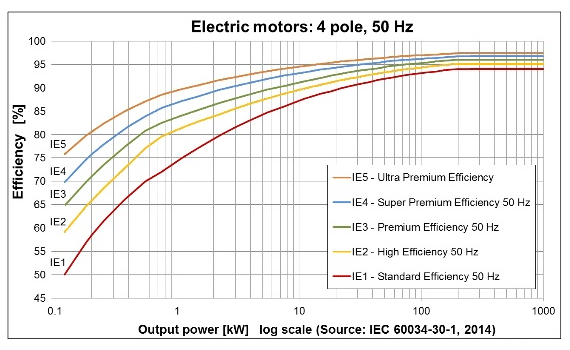

E[Efficiency] --> F[Pout/Pin]Efficiency Comparison

General Efficiency Formula:

Radial Flux:

- Mature technology with optimized designs

- Well-understood losses and mitigation

- Efficiency:

depending on size/design

Axial Flux:

- Potentially higher efficiency due to:

- Shorter end turns:

- Better heat dissipation:

- Optimized magnetic circuit

- Shorter end turns:

- Efficiency:

in well-designed systems

Speed Capabilities

Mechanical Speed Limit:

where

Radial Flux:

- Standard bearings and mounting

- Rotor dynamics well understood

Axial Flux:

- Lower rotational inertia:

(disc) vs (cylinder) - Axial magnetic forces:

- Potential for higher acceleration:

8. Design Trade-offs

graph LR

A[Cost] --> A1[Radial: Lower]

A --> A2[Axial: Higher]graph LR

B[Power Density] --> B1[Radial: Good]

B --> B2[Axial: Excellent]graph LR

C[Manufacturing] --> C1[Radial: Mature]

C --> C2[Axial: Complex]graph LR

D[Cooling] --> D1[Radial: Limited]

D --> D2[Axial: Superior]Advantages & Disadvantages

| Aspect | Radial Flux | Axial Flux |

|---|---|---|

| Manufacturing | Mature, standardized | Complex, specialized tooling |

| Cost | Lower (volume production) | Higher (specialized) |

| Power Density | Good for small-medium sizes | Excellent for large diameters |

| Cooling | Limited surface area | Large flat surfaces |

| Bearing Loads | Radial forces only | Axial + radial forces |

| Scalability | Linear with volume | Cubic with diameter |

Cost Analysis:

9. Applications & Selection Criteria

flowchart TD

A[Motor Selection] --> B{Application?}

B -->|Standard| C[Radial]

B -->|Space Limited| D[Axial]

B -->|Cost Critical| C

B -->|High Power| DChoose Radial Flux When:

- Standard industrial applications

- Cost is primary concern:

- Proven reliability required

- Small to medium power ratings (

) - Established supply chains needed

Choose Axial Flux When:

- Space constraints (pancake form factor):

- High power density required:

- Direct drive applications:

- Wheel hub motors:

- Large diameter, low speed:

,

Selection Formula:

10. Future Developments

timeline

title Motor Technology Evolution

2020 : Traditional Radial Flux

: Silicon Steel Cores

: Ferrite Magnets

2025 : Advanced Materials

: Amorphous Steel

: Rare Earth Magnets

: Better Thermal Management

2030 : Manufacturing Revolution

: 3D Printed Components

: Automated Winding

: Cost Reduction

2035 : Next Generation

: AI-Optimized Designs

: Novel Cooling Systems

: Modular ArchitectureRadial Flux Evolution

- Advanced materials (rare earth magnets, amorphous steel)

- Improved manufacturing techniques

- Better thermal management:

- Higher speed capabilities

Axial Flux Innovation

- Manufacturing cost reduction

- 3D printed components

- Advanced magnetic materials:

- Integrated thermal management

- Modular designs for scalability

Technology Readiness Levels:

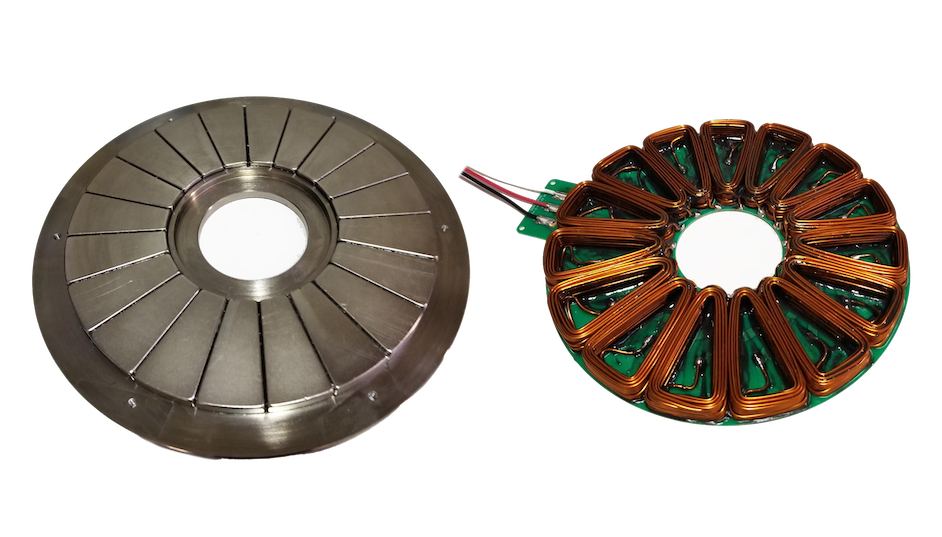

PCB Motor Adaptation of Axial Flux Design

- PCB motors represent the ultimate evolution of axial flux motor technology, leveraging printed circuit board manufacturing to create ultra-flat, highly efficient motors.

- The inherent disc geometry of axial flux motors translates perfectly to PCB construction, where copper windings are etched directly onto flat substrates rather than wound with traditional wire.

Key Adaptations: - Flat spiral windings replace bulky 3D coils, eliminating end turns entirely

- Multi-layer PCB stacks create concentrated magnetic fields in minimal axial space

- Precise manufacturing tolerances from PCB fabrication enable tighter air gaps

- Integrated cooling through copper pours and thermal vias in the PCB substrate

References